|

|

Click on the image to see the movie taken during shearing.  |

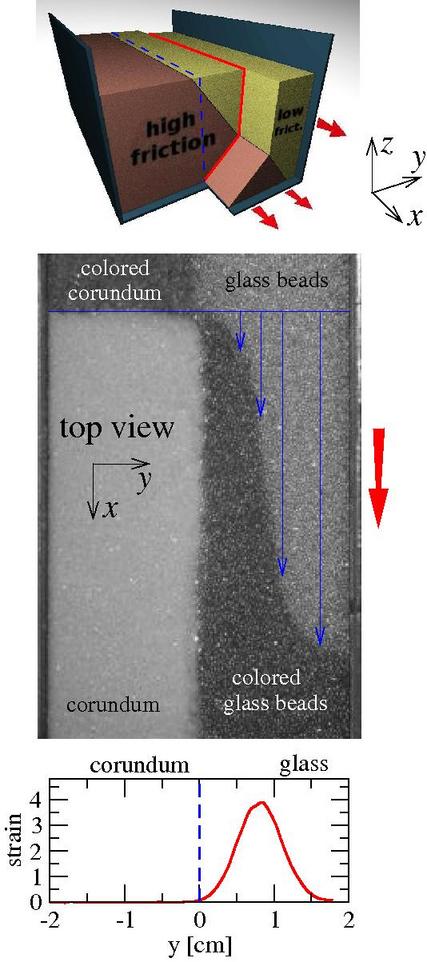

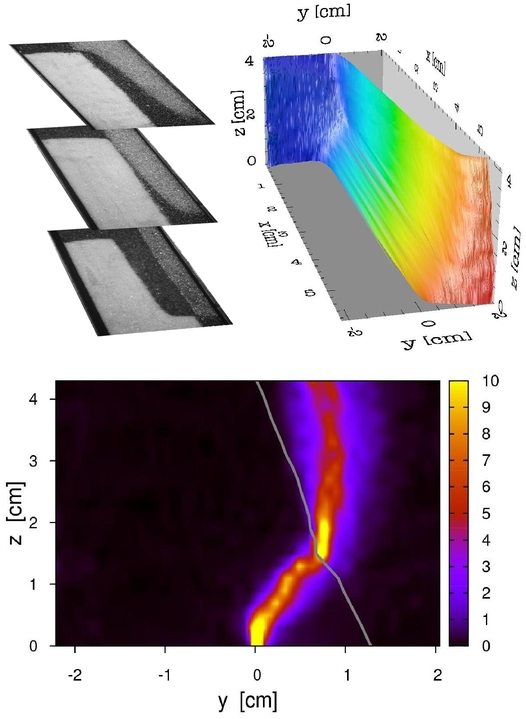

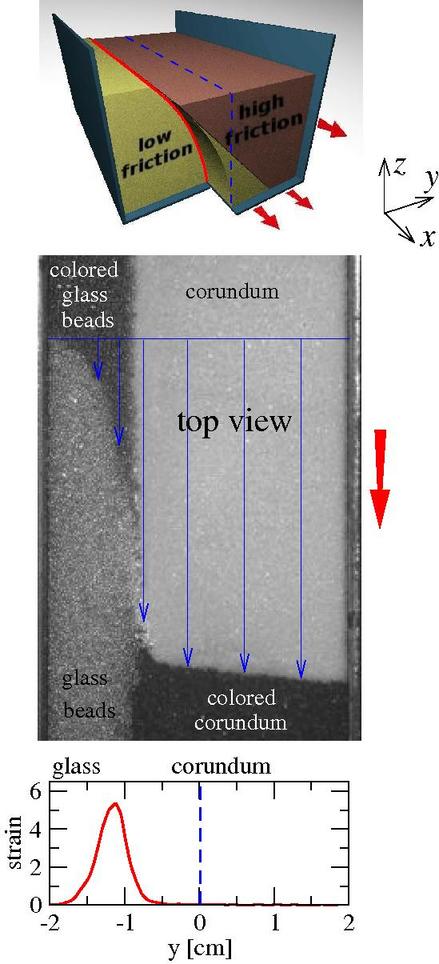

3D reconstruction

After

each experiment the displacement profile in the bulk d(y,z) was reconstructed by

removing the top surface of the material carefully layer by layer.

These profiles are presented in the images below for both

refraction and deflection, together with sample images taken during the

excavation process. The gradient of the displacement provides the local

shear strain inside the material in the y-z plane which is shown at the

plots below the displacement profiles. In the first case the zone,

starting from the bottom, takes a short path towards the

interface and by reaching the low friction region it changes direction

abruptly and heads straight to the top. In the second case the zone

starts in the low friction material it deflects to avoid the high

friction region even if it takes a much longer path. Further

measurements to explore the internal deformation using MRI are on the

way.

|

Click on the image below to see a movie of the subsequent layers from top to bottom during removing.  |

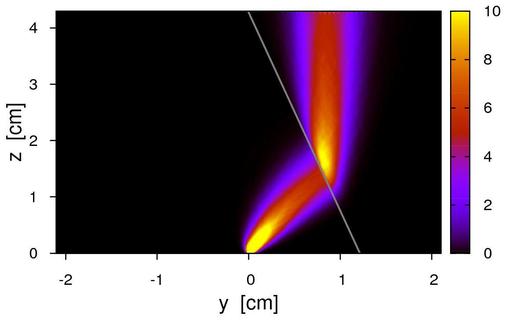

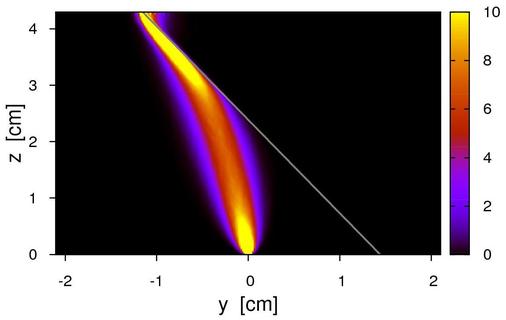

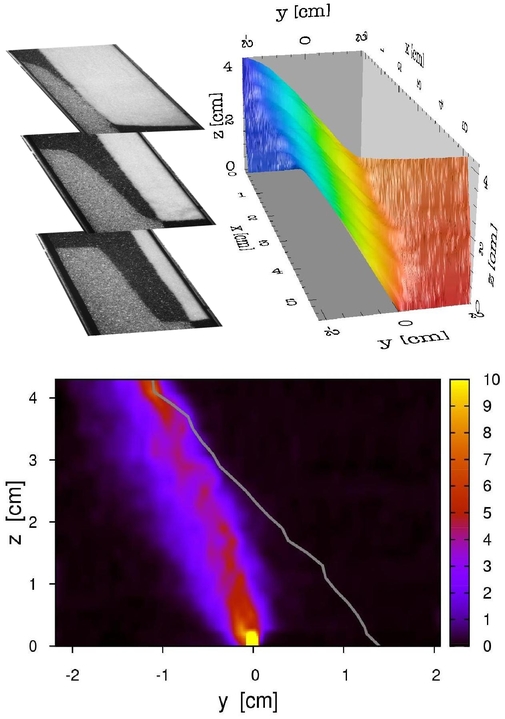

Numerical simulation results

The computer simulation is

performed based on the fluctuating narrow band model [Phys.

Rev. Lett., 92, 214301

(2004), Phys.

Rev. E 75, 011305 (2007)].

According to this model the deformation occurs along the weakest

sliding surface through the random medium. An ensemble average over the

random realizations of the granular medium provides the shape and width

of the shear zone. A cross section of the numerical system

is shown below

for two simulations corresponding to the two experimental systems.

(click on the images to

magnify)

|

|

|

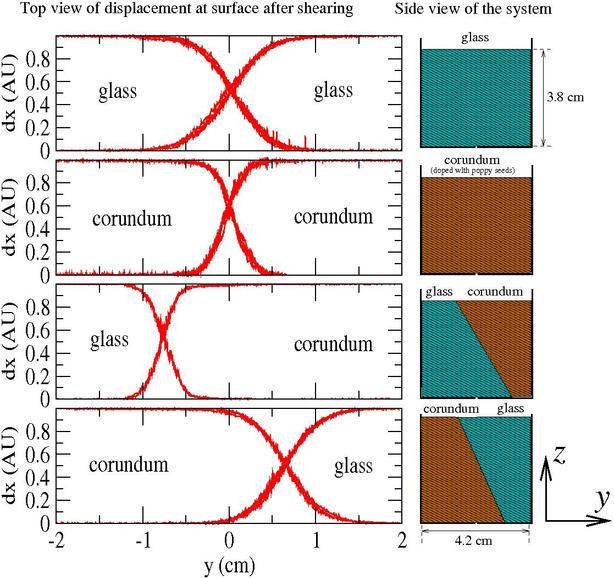

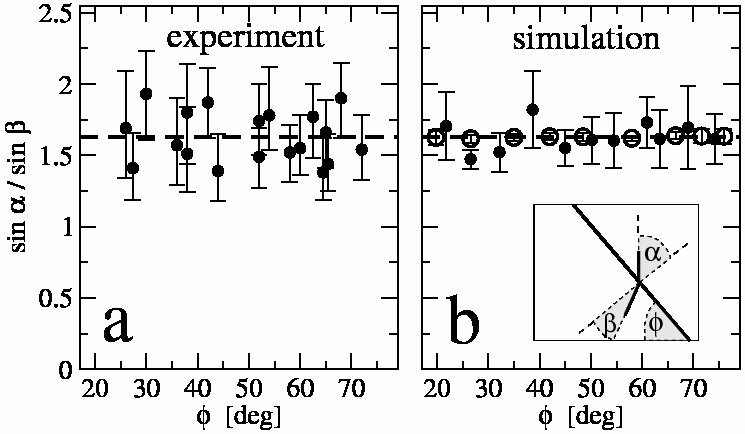

Verifying Snell's law

Numerous experiments and

simulations have been performed to test whether Snell's law is valid

for this system. As described above it is expected that the relative

index of refraction is replaced by the ratio of the

effective frictions. We estimated the ratio of the effective frictions

by measuting the angle of repose for both materials and the

experimentally obtained value was 1.63. We compare this number with the

raio of the sines of the angles of incidence (see inset of graph b

below). The ageement is very good for both experiments and simulations.

Experimental details

Further experimental results