- High-Temperature Laboratory

- Electrodeposited Nanostructures Laboratory

- Laboratory of Colloidal Chemistry

- Atomic-Absorption Spectrometer

- Reactive Discharge Plasmas and Chemical Vapour Deposition

- Heavy-ion Cascade Implanter (NIK)

High-Temperature Laboratory

- Induction melting

- NEW High frequency induction generator for cold crucible, graphite or ceramic crucible melting and sintering

- Type: Stanelco STX25-DF1

- Operation frequencies: 400 kHz and 1 MHz

- Output power: 25 kW

- NEW High frequency induction generator for cold crucible, graphite or ceramic crucible melting and sintering

- High temperature annealing

- NEW Carbolite high temperature horizontal tube furnace (CTF/18/300)

- 1800°C maximum operating temperature

- Maximum continuous operating temperature is 1700°C

- Molybdenum disilicide heating elements

- Thermocouple: Pt20%Rh / Pt40%Rh

- Programmable controller with 8 stages

- Over-temperature protection

- Tube guards and supports for extended tube length (1200 mm)

- Tube materials: quartz or ceramic (above 1000°C only ceramic to be utilized)

- 300 mm heated lengths (homogeneous zone: 200 mm), with 90 mm diameters

- Separate tube for each user

- Vacuumable to 10-3 bar

- Modified atmosphere with nitrogen 5.0 or argon 5.0

- Quartz, ceramic or glass laboratory tools, and table for sample preparation

- HP ProBook 430 G2 workstation for data processing

- NEW Carbolite high temperature horizontal tube furnace (CTF/18/300)

- Electron-beam and resistance-heated vapourization in high vacuum (10-7 Pa).

- Grinding equipment to achieve mechanical alloys and nanophases.

|

|

| Electron-beam vapourizer | High-vacuum oven |

Electrodeposited Nanostructures Group ↑

This laboratory consists of several smaller units, in which many approaches of electrochemical manufacturing can be deployed. There is a cryostat for producing nanoporous aluminium-oxide templates (a recirculatory-fluid cryostat and four power supplies for electro-deposition). Workstations with five different types of potentiostat can produce electrochemically deposited metal samples. One of them is connected to an SRS-200 quartz-crystal microbalance, which enables in-situ monitoring of mass changes. This array of instruments is able to produce homogeneous alloys, nanocrystalline metals, multi-layer metallic samples, and using templates, it can produce nanowires in an electrochemical process. Moreover, this laboratory operates an SEM-EDS device to examine sample composition, and a sputter coater by Denton Vacuum Desk V equipment. The latter equipment may sputter metallic layers with target size of about 75 mm. Three different sputtering target materials are provided (silver, gold and platinum). The sputter coater can be controlled by its own touchscreen interface, thus can be used off-line.

Laboratory of Colloidal Chemistry ↑

Our laboratory of colloidal chemistry is equipped with instruments for inorganic preparation in an atmosphere with reduced dust content. The main parts are: teflon-coated reaction bomb calorimeters in the 25 ml.250 ml range, used for acidic decomposition and hydrothermal synthesis up to 250 °C; fast-dialysis units; centrifuges (up to 8500 rpm, 6 x 100 ml) for density-gradient separation; devices for electrochemistry-based measurement (pH, redox potential, F ion, nitrate ion, ionic strength, oxygen concentration in solution for tiny samples too); ball milling.

Atomic-Absorption Spectrometer ↑

After its recent acquisition, we have set up a new high-resolution atomic-absorption spectrometer (AAS) of type Analytik Jena ContrAA700. This state-of-art device can analyze the composition of solid and fluid-phase inorganic samples, several constituents in parallel. It implements techniques, e.g. light source with continuous spectrum, high-resolution optics, high-sensitivity detector, which provide flexibility in a wide range of applications. This includes examination of extremely heat or chemically resistant materials and microgram-sized or even smaller samples. The chief range of application so far spans examination of new material systems developed in out institute, and analysis of environmental matrices' composition.

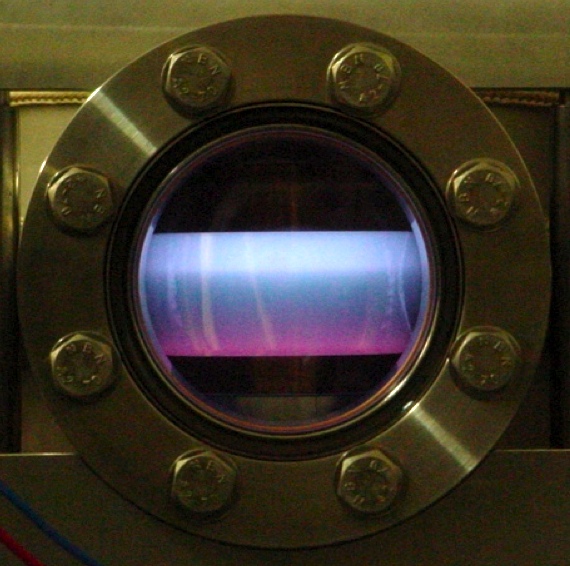

Reactive Discharge Plasmas and Chemical Vapour Deposition ↑

Electric gas-discharge plasma in low-pressure He atmosphere

In the micowave-gas-discharge plasma reactor, one can grow oxide nanostructures in atmospheric-pressure post-discharges. The atomic processes can be monitored as well. In the radio-frequency low-pressure and atmospheric-pressure discharge, we can functionalize conductive and insulator surfaces in a plasma environment. In the chemical-vapour-decomposition device, doped diamond thin layers can be grown, as well as hydrogen-plasma treatment can be carried out.

Heavy-ion Cascade Implanter (NIK) ↑

Our NIK machine is an ion accelerator of the heavy-ion cascade implanter type. It is capable of accelerating many ion types ranging from hydrogen to bismuth; its terminal voltage is 100.450 kV. The lateral homogeneity of ion irradiation is ensured by an electrostatic system, whose cross-section is 25 x 50 mm2, the maximum ion current is 1.100 .A. The temperature of irradiated sample can be controlled between ambient temperature and 600 °C, it is monitored by an infrared thermometer. Changes in the state of sample can be supervised with a W88 spectroscopic ellipsometer from J.A. Woollam Co.